How do I determine the intended use of HVAC access doors and panels?

HVAC access doors and panels provide easy and safe access to the interior of ductwork, walls and ceilings, HVAC housings, welded grease ducts, and enclosures.

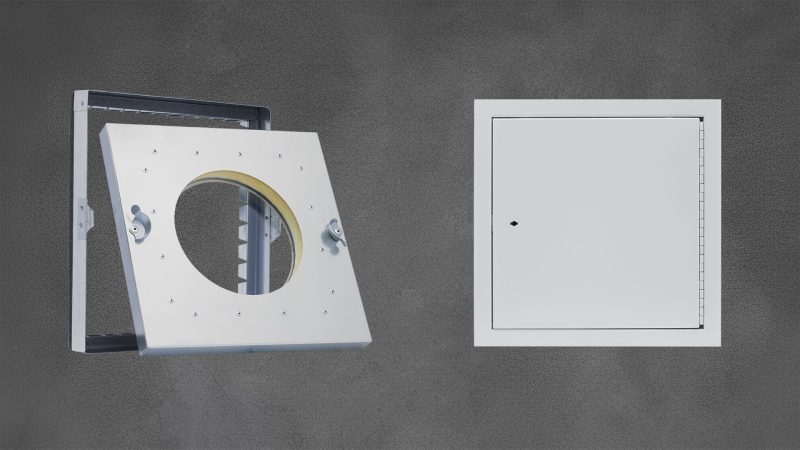

- Access doors, or duct access doors are installed directly into ductwork. They offer easy access to the inside of ducts, plenums, and air handling casings.

- Access panels are installed into walls and ceilings to provide access to the mechanical, electrical, or plumbing components secured within.

When determining the intended use of a HVAC duct access door or panel, consider the following:

- If building an access door, does it need to be large enough for a human to enter?

- If building an access panel, will it be installed on the wall or the ceiling?

- Will this access door or panel be installed in an interior space or on the exterior of a building?

- Are there operating pressures or air leakage specifications to consider?

- Are there environmental factors, like moisture or chemical contaminants in the airstream, in the installation location?

- Is the ductwork insulated?

- Is the door/panel part of a fire-rated barrier?

What standards do HVAC access doors and panels need to satisfy?

HVAC access doors and panels are built in compliance with regulatory standards to maintain safety and ease of access.

Fire resistance: The National Fire Protection Association (NFPA) rates the fire resistance of walls and the fire protection of windows, doors and panels, with the rating corresponding to the amount of time in hours a space can withstand exposure to fire. Duct access doors and panels need to carry a fire protection rating equal to or better than the space in which it is installed, ensuring there is time for people to be evacuated and firefighters to respond.

Construction: As duct access doors are installed directly into ductwork, and act as part of the duct when not being used as an access point, they may be required to be built from similar materials and to similar operating conditions.

Size: When installing an access door or panel that a human is intended to enter, the minimum required size is 20"x20".

What materials should I consider when specifying HVAC access doors and panels?

When specifying HVAC access doors and panels, consider the material of the door or panel, the material of the gasket, and the structure and profile of the gasket.

Metal Construction

HVAC access doors and panels are made of metal. When specifying a metal, consider the door or panel's intended location and use case.

- Galvanized Steel: The most common material used for ductwork, galvanized steel is chosen to match the construction of a duct access door and the surrounding ductwork.

- Aluminum: This lightweight, rust-resistant metal is used for access door and panels installed in high humidity settings.

- Stainless Steel: Corrosion-resistant stainless steel is chosen for environments where ducts exhaust air that contains harsh chemicals or particulates.

Gasket Materials

Gaskets create a seal that prevents air from leaking into or out of a HVAC access door or panel. Different types of gasket materials offer different benefits:

- Neoprene: A cost-effective polymer that provides a workable seal, and is widely used across the industry.

- EPDM Rubber: This polymer carries a high resistance to heat, light and the weather, making it ideal for outdoor applications.

- Silicone: A material chosen for its wide temperature range, as it stays pliable in extremely high and extremely low temperatures.

- Woven Ceramic Fiber: Used in commercial kitchens, this material locks in grease and other flammable liquids to reduce the risk of leaks and fires.

Gasket Structure and Profile

The material structure and profile of a HVAC access door or panel gasket affects its performance and overall cost:

- Open-cell vs Closed-cell: Gasket materials can be made open-cell or closed-cell, which influences their hardness and permeability. Closed-cell is harder and creates a tighter seal, while open-cell is softer and creates a lighter seal. Closed-cell is more expensive than open-cell, so when specifying, the choice comes down to performance versus cost.

- Bulb/Profile-type vs Flat type: Bulb- or profile-type gaskets create tighter seals on irregular surfaces but are more costly, whereas flat-type gaskets operate as one-size-fits-all and are less expensive. When preventing leakage is of the utmost importance, bulb-type gaskets should be considered.

Additional Considerations

HVAC access doors and panels can be further customized depending on the needs of the installation:

- Insulation: Access doors and panels may be insulated to prevent conditioned air from losing or gaining heat before it is delivered to rooms.

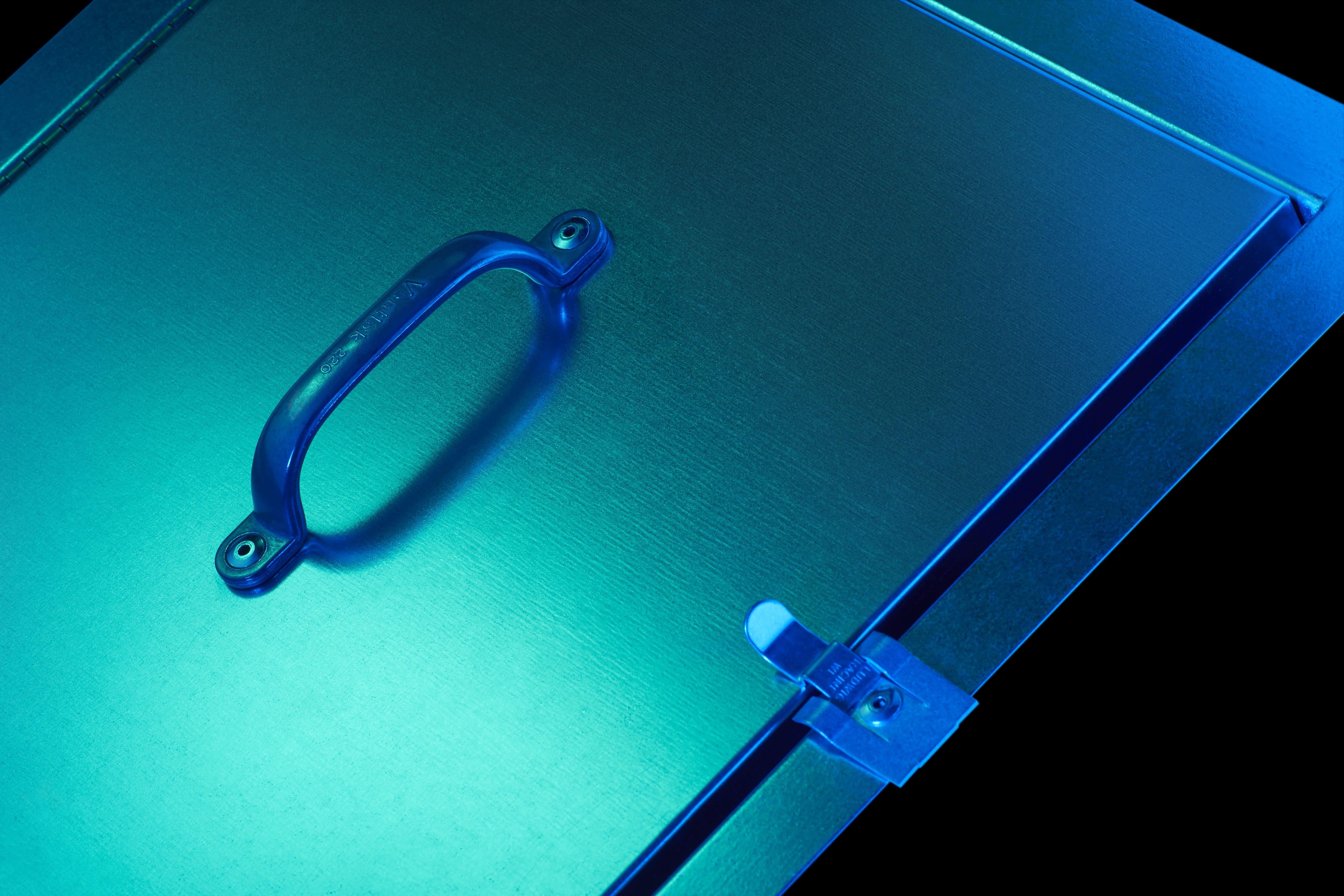

- Security: For added security, access doors and panels can be built with security features such as rounded edges, heavy gauge materials, and keyed access.

- Aesthetic Considerations: Manufacturers may offer framing options and primer finishes that help access panels blend into the surrounding walls or ceilings.

Why KEES

At KEES, we design and build HVAC access doors and panels with an emphasis on convenience, safety, and quality. We offer a wide range of models that can be customized to our clients' exact specifications to meet unique access requirements.

Customization: From added security features to weather resistance, KEES offers our signature customization services for HVAC access doors and panels. We build high-volume standard configurations in addition to one-of-a-kind access doors and panels to satisfy our clients' exact specifications.

Speed: Count on KEES for fast construction and delivery of HVAC access doors and panels. We have the fastest lead times in the industry for non-stock items.