Industrial exhaust hoods remove exhaust, fumes, and airborne particulates from commercial and industrial buildings. When industrial hoods are custom-designed for their environment, they can increase production efficiency and worker safety and reduce operating costs.

What are the main applications of industrial hoods?

Industrial hoods remove harmful and dangerous air from industrial settings, such as:

Manufacturing: Industrial hoods serve many purposes in manufacturing – removing heat and smoke from heat-making processes like welding or kiln firing, exhausting fumes from painting and finishing, and taking out airborne particulates generated from grinding.

Pharmaceutical: Industrial hoods remove contamination created by pharmaceutical manufacturing processes to maintain a sterile and safe production environment.

Chemical Processing: Industrial hoods protect workers from hazardous chemicals by removing and expelling toxic fumes.

By drawing out unwanted and unclean air, industrial hoods not only ensure worker safety and compliance with safety standards, but also improve the efficiency of airflow in a building, leading to lower operating costs.

What are the characteristics of industrial hoods?

The following characteristics should be considered when specifying an industrial hood:

Materials: Industrial hoods can be built out of a variety of materials with qualities suited for different use cases:

Raw steel and galvanized steel are used in low-temperature, non-chemical applications.

Rust-resistant aluminum and stainless steel are best in wet and humid environments.

Stainless steel’s high melting point makes it useful for high-temperature applications.

Polymer hoods excel when working with chemicals that corrode metal.

Dimensions: Industrial hoods remove air in cubic feet per minute (CFM). Larger hoods achieve a greater CFM.

Shape: The shape and size of an industrial hood can be customized to its use case. For example, hoods can be built to fit above or around a particular machine, enclosed to maximize airflow efficiency, or lowered from the ceiling to better collect dense air.

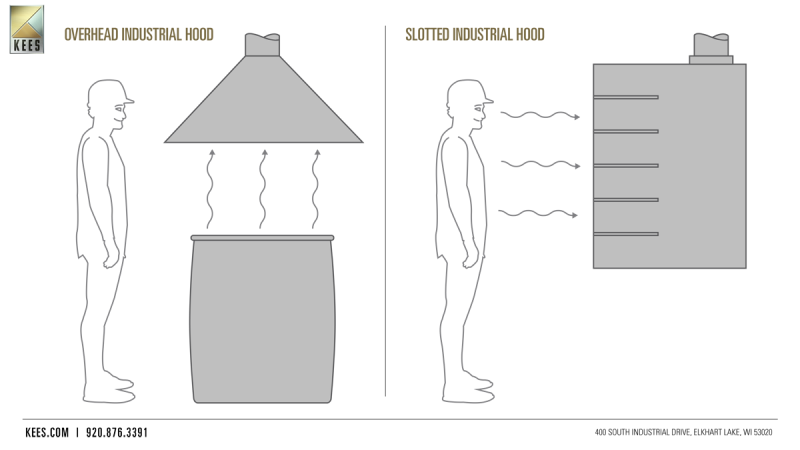

Orientation: Orientation refers to where an industrial hood will be placed as well as which direction it will pull in air from. Ceiling-mounted overhead hoods take up air from directly below, whereas wall-mounted slotted hoods draw in air horizontally, away from workers' faces.

Movable Pieces: Optional movable pieces, such as baffles, skirting, and removable hood parts, allow for on-site direction of airflow, as well as easier cleaning.

What should you consider when specifying industrial hoods?

Considering the following questions when specifying industrial hoods:

What process will the industrial hoods be exhausting from? Does it involve corrosive chemicals, lots of water, or high temperatures? The process being done will determine the most suitable construction material.

What is the geometry of the process? How much space does it take up, including overhead? Is the process stationary or does it move around the environment? Knowing where a hood is to be placed will inform its shape and dimensions.

Where will the hoods connect to exhaust ductwork? Is the ductwork in the ceiling or flexible? Is it easy to access? Where the exhaust dust connections, i.e. collars, are located will dictate the shape of the hood, so it can properly capture exhaust and facilitate its removal from the building via the ducts.

Why KEES?

KEES has over 50 years of experience building custom HVAC solutions for a wide range of industrial applications. We work one-on-one with our clients to individually design industrial hoods that satisfy exact specifications and use cases.

Customizability: KEES builds custom industrial hoods that maximize the safety and efficiency of our clients’ plants, laboratories and forges. Our hoods can be customized by materials, dimensions, shape, orientation, mounting options, number of duct collars, and more.

Experience: With over 50 years of industry experience, KEES knows the questions sales reps and engineers have about industrial hoods – and is prepared to answer them.

Speed of Delivery: KEES specializes in custom HVAC infrastructure. Our manufacturing processes are highly optimized, enabling fast fabrication of one-of-a-kind solutions.