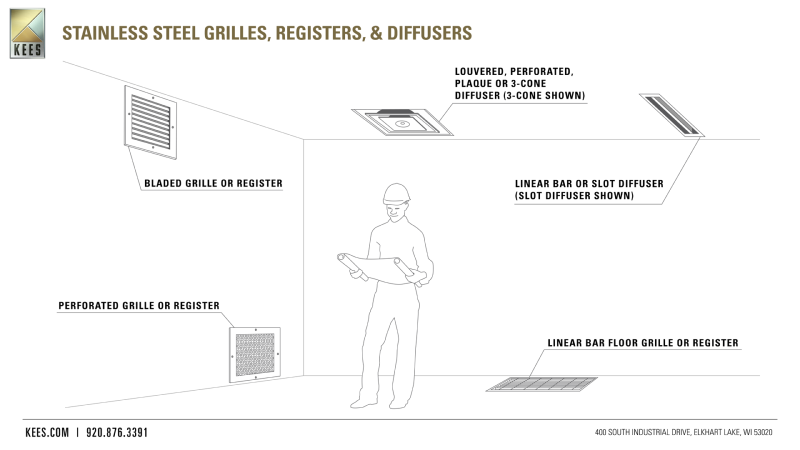

Grilles, registers, and diffusers (GRD), installed in ductwork openings, deliver air into and remove air from interior spaces. GRD made from stainless steel are used in harsh environments where corrosion resistance, cleanliness, and durability are prioritized.

What are the benefits of stainless steel grilles, registers, and diffusers?

Stainless steel grilles, registers, and diffusers are prized for their ability to withstand damage from harsh, corrosive chemicals, high humidity, and other environmental hazards.

Corrosion and rust resistance: Stainless steel resists rusting and corrosion from repeated exposure to water, high humidity, and harsh chemicals, making it a great choice of material for environments that work with chemicals or have heavy sanitation practices.

Longevity: Thanks to stainless steel’s bevy of resistances, stainless steel grilles, registers, and diffusers last longer than GRD made with aluminum or plastic, needing to be replaced less often.

Aesthetics: Outside of industrial environments, stainless steel grilles, registers, and diffusers are chosen by architects and designers for their aesthetic qualities.

What are common applications of stainless steel grilles, registers, and diffusers?

Common applications of stainless steel grilles, registers, and diffusers are in industrial or manufacturing environments with high humidity, frequent sanitation, and harsh chemicals:

Cleanrooms: Stainless steel GRD are chosen in cleanrooms to help maintain a sterile environment, as their resistance to rust makes them easy to sanitize.

Pharmaceutical and medical laboratories: Stainless steel GRD resist corroding from the harsh chemicals and particulates created by pharmaceutical and medical production processes.

Food processing facilities: Stainless steel GRD can withstand the harsh chemicals and frequent washings used to sanitize food processing facilities.

Water treatment plants: Stainless steel GRD resist damage from water, chemicals, and humidity, making them an excellent choice for water treatment plants.

Data Centers: Stainless steel GRD provide durable, cleanable solutions for critical environments with tightly controlled conditions.

What should you keep in mind when specifying stainless steel grilles, registers, and diffusers?

When specifying stainless steel grilles, registers, and diffusers, here are some questions to keep in mind:

Which alloy is specified? Stainless steel grilles, registers, and diffusers can be made from two high-quality alloys, 304 or 316. Stainless steel 316 offers enhanced corrosion resistance compared to 304, but is more expensive. This price differential should be taken into consideration when reviewing the project’s budget.

Where will the GRD be mounted? The intended mounting location of a grille, register, or diffuser will inform its construction and design; refer to the designer's plans to order the correct model for the right location.

What accessories does it need? Engineers and designers may request specific accessories for grilles, registers, and diffusers. Common types of accessories include opposed-blade volume dampers that regulate airflow, filters that further clean the air, and hinges or removable faces that make cleaning grilles easier.

Why KEES

KEES specializes in stainless steel construction. Our mastery over the material results in skillfully designed grilles, registers, and diffusers built to our client’s exact specifications.

Experience: Some manufacturers find stainless steel hard to work with. Those manufacturers aren’t KEES. Our stainless steel GRD are backed by our decades of experience manipulating this extra-durable material and built to last.

Customization: KEES offers a breadth of options for stainless steel GRD. We customize all product orders to spec; when it comes to unique sizing, the bigger the better.

Speed: Count on KEES when you need a product ASAP. Our flexible production environment is fine-tuned for quick turn-around times and fast shipping.